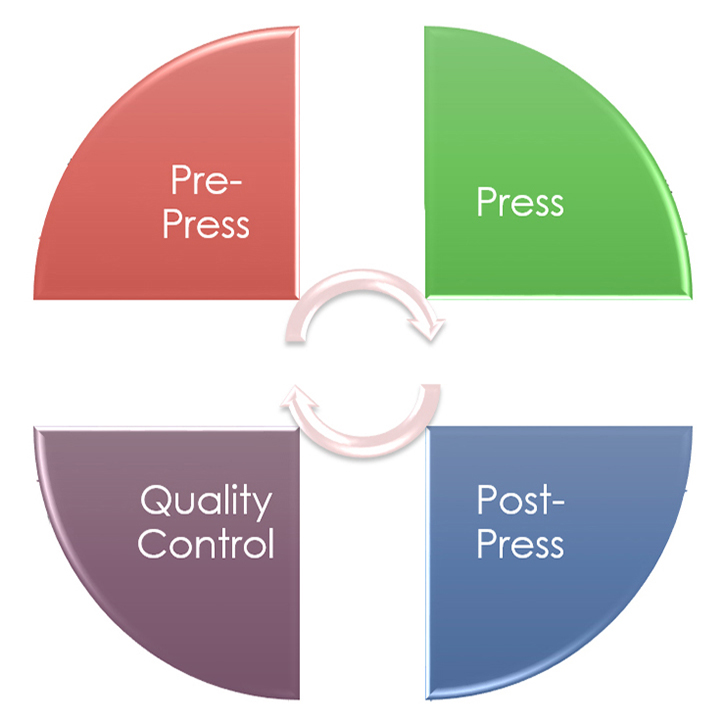

- Artwork development station giving us a wide variety of designs and helping us achieve the right colors

- Advanced Platemaking center enabling us to deliver better printing results

- Quality cutting machines in order to cut the material in required sizes with precision

- Preparation of the Job to go on the press following a thorough study of the job, and analysis of substrates to achieve accurate and desired results with an In-House PrePress Setup

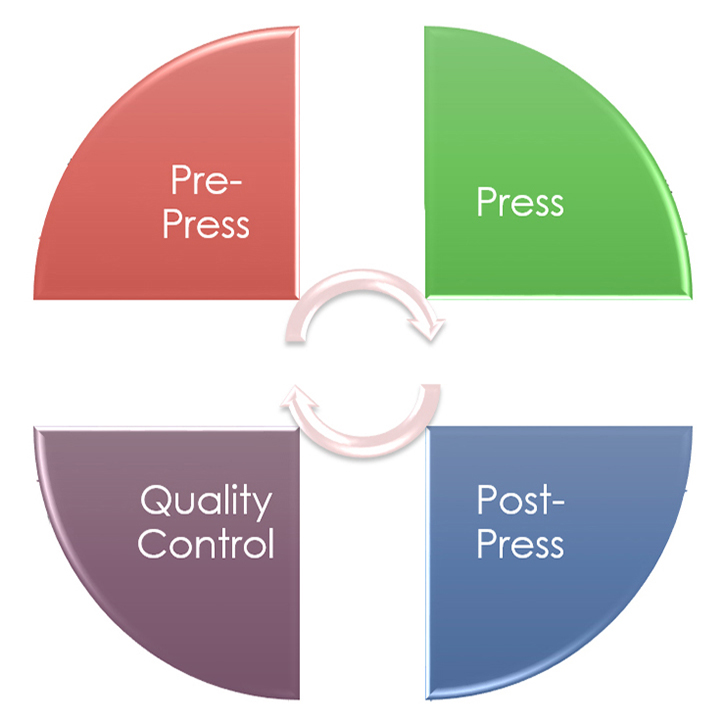

- Quality Assessments of all inputs included in the Production Process and Finished Goods with Precision using a plethora of Testing Equipment like SpectroDensitometer & Online Camera Sorting Machines

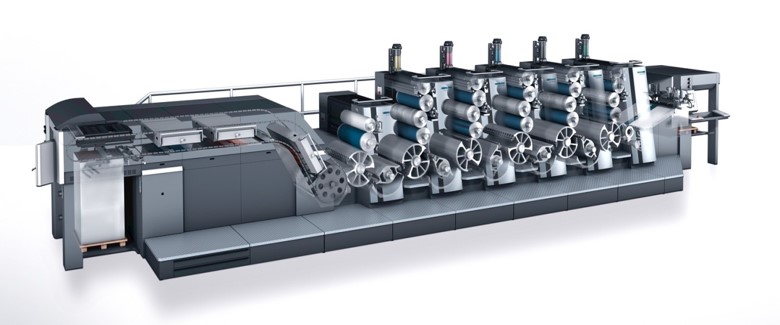

- Highly advanced printing Machines of Heidelberg, Germany delivering quality transformation of designs on virgin boards

- Highly advanced printing machines of Komori, Japan for supplementary literature requirements such as Leaflets and Inserts with perfector

- Presses are equipped with Online Coating Systems for streamlined print production

- State-of-Art Printing Machines to Print Multi-colour (1-6) Mono Cartons and Leaflets with a wide range of Valueadditon options and equipment from Heidelberg, Germany & Komori, Japan

- Value-addition stations including UV Coating, Foil Stamping and Lamination

- Insert folding machines enabling rapid conversion of Multi-fold Inserts at high speeds

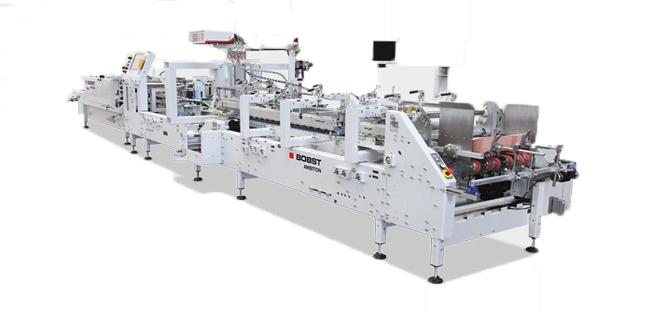

- Automated high speed medium and large format Die Cutting machines of Bobst, Switzerland enabling us to manufacture a wide product range with distinctive carton styles

- High speed automatic pasting and locking machines delivering quality finished products

- Automatic high speed machine for application on unfolded cartons to apply track and trace labels

- Providing a Variety of Finishes to the Printed Material and subsequently Converting it into Packaging Boxes with Cutting-edge Machinery from Bobst, Switzerland and Leaflet Folding Machines from India